Artificial Cells, Smarter Materials

Northwestern scientists engineer materials that adapt like nature

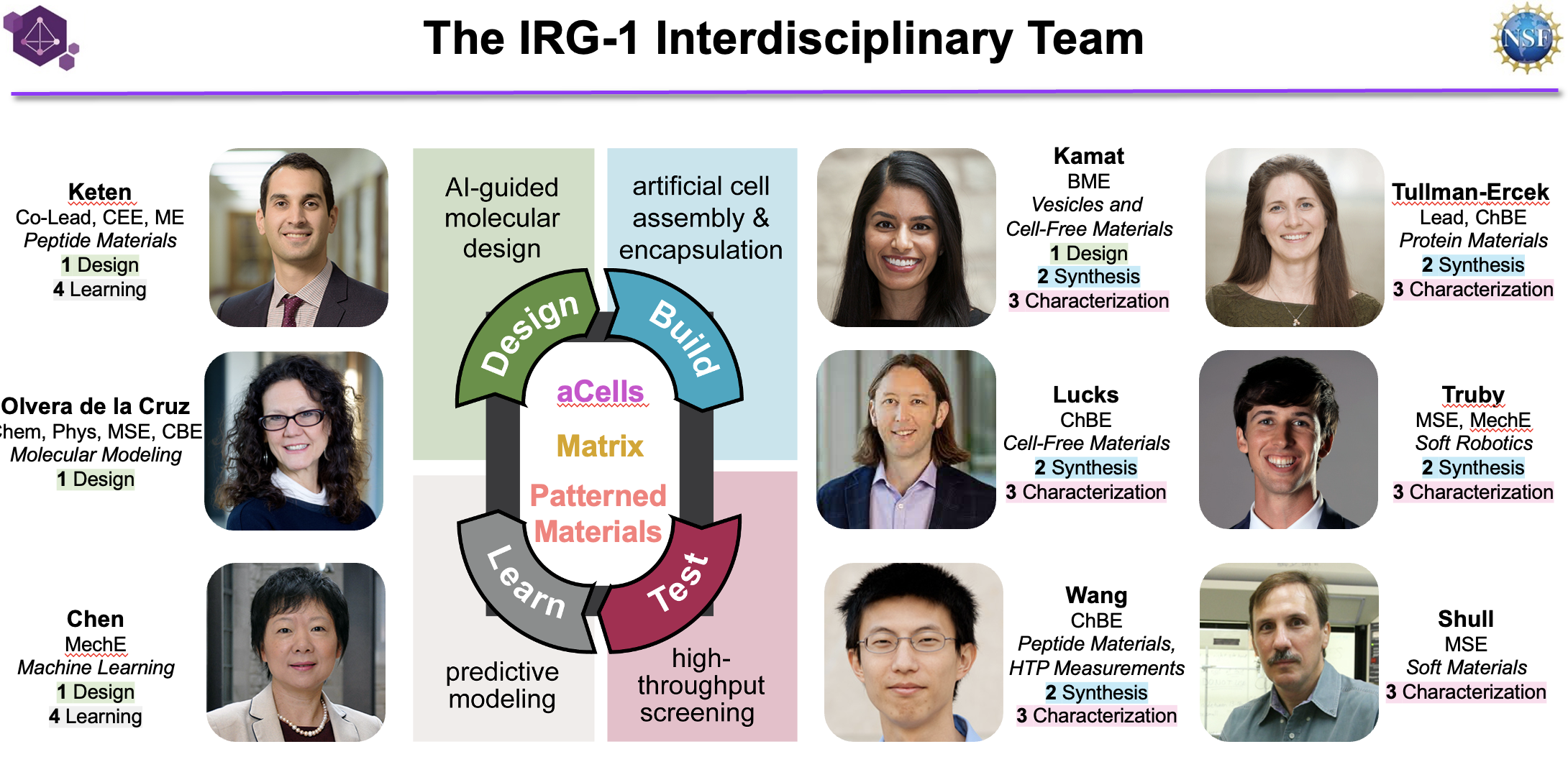

A Northwestern research team led by Danielle Tullman-Ercek (chemical & biological Engineering) and co-led by Sinan Keten (mechanical and civil/environmental engineering), is developing bioresponsive materials—materials that change when their surroundings change. Nature already does this: an octopus shifts color; a banana peel darkens as it ripens. Programming similar behavior could enable smarter camouflage or food packaging that clearly signals spoilage.

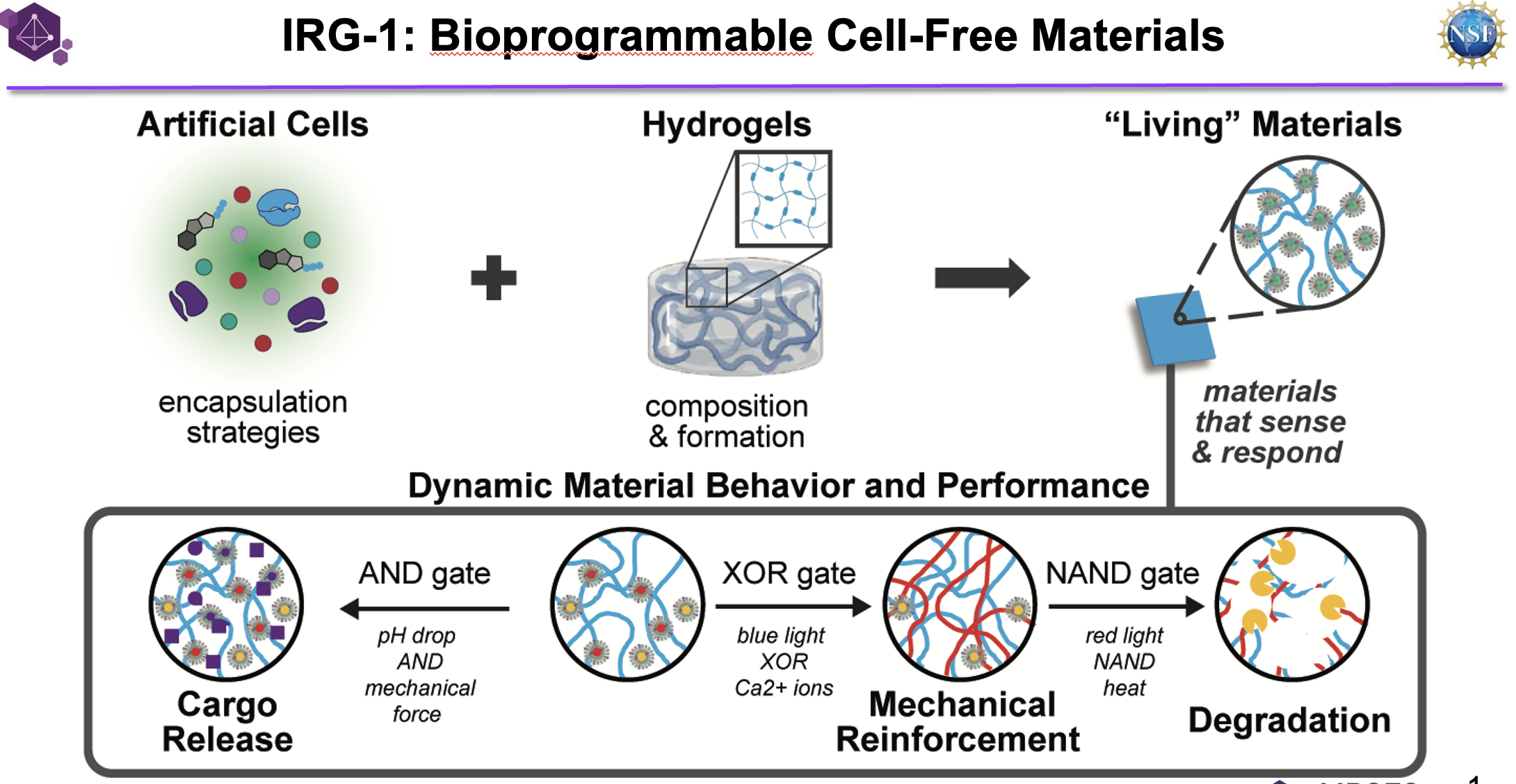

Here's how it works: the team creates soft gels embedded with tiny artificial cells—microscopic compartments made from lipids or polymers that mimic safe, simplified versions of living cells. Inside each compartment is a cell-free gene expression system (the “machinery” that reads DNA/RNA without using living cells) along with biosensor circuits that detect specific signals (for example, a change in pH, the presence of a toxin, or a spoilage metabolite). When a trigger is detected, the circuit activates a programmed response, such as a color or fluorescence change, or a local change in gel stiffness, so the material effectively “senses and acts.” By arranging different artificial cells in precise patterns using 3D printing or light-based photopatterning, the researchers create logic across the material (AND/OR-type behavior) so it can interpret multiple inputs simultaneously. Computer simulations and machine-learning tools help select sensor designs and spatial arrangements that optimize speed, accuracy, and stability.

This research is part of the Northwestern University Materials Research Science and Engineering Center (NU-MRSEC)—Northwestern’s long-running, NSF-supported research hub in materials science and engineering.

In the project’s first two years, the team created sensors that work reliably inside gels, built simulation and ML tools to guide designs, and demonstrated manufacturing by 3D printing and photopatterning. “Since launch, we’ve taken huge strides,” said Tullman-Ercek, who also co-directs Northwestern’s Center for Synthetic Biology. “We’ve built new sensors that respond to our target triggers inside the gel and created computational tools that speed up the design-build-test-learn process. Equally importantly, we built a strong interdisciplinary, collaborative team that has a lot of fun working on this cutting-edge project together.”

The team’s scope encompasses materials science and various engineering disciplines, combining biology, materials, design, and advanced manufacturing.

About the hub: As part of the national MRSEC network (active for decades), NU-MRSEC advances discovery through two interdisciplinary research groups (IRG-1: Bioprogrammable Materials; IRG-2: Orchestrated Iontronics), a seed-funding program, shared facilities, and education/outreach that help move new ideas into the lab, classroom, and marketplace. Learn more

—Matt Golosinski